CUSTOM ENCLOSURE & BOX BUILD ASSEMBLIES

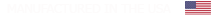

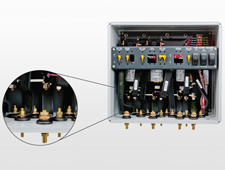

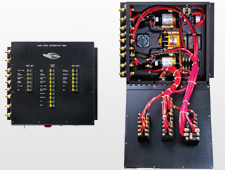

Paneltronics designs and manufactures custom enclosure box-build assemblies that efficiently consolidate multiple parts, components, and functions into a central control unit. These pre-assembled units can be designed for use in engine rooms, engine compartments, or any conveniently accessible location where centralized control is required.

Our engineering team carefully evaluates every design element and incorporates all specifications for size constraints as well as mounting, vibration, environmental and accessibility requirements. These are coupled with the specific electrical and mechanical requirements to design an optimal, cost effective solution. Our team can also design turnkey solutions from concept to finished product or build-to-print to satisfy specific OEM customer requirements.

These high quality enclosures are designed for rugged environments such as off-highway, heavy truck, construction, or marine applications. They simplify installation by reducing labor and providing a central location for operation and/or troubleshooting.

Click on thumbnail below to view larger image.

Solutions:

Paneltronics' enclosure box-build assemblies provide efficient consolidated assembly solutions for several common functions and requirements including:

- Ignition protection

- Common buses

- Control module protection

- Circuit protection

- Monitoring devices

- Battery switching

- Solenoids

- Sensors

- Relays

Features:

Features of our enclosure box-build assemblies include:

- Ignition protection surface or bulkhead mount options

- Wire access ports

- Multi-pin bulkhead connectors

- Corrosion resistant aluminum fabrication

- Hinged front panel faces or covers

- High amp, custom flexible buses

- High amp power feed-through studs

- Polyurethane or powder coat finishes

- Optional pre-fabricated fiberglass or plastic enclosures

Benefits:

Enclosure box-build assemblies benefit the production process with:

- Reduced installation labor and increased productivity

- Consistent electro-mechanical assemblies

- A central location for key functions and components

- Reduced wiring errors on the production line

- Go-to point for system troubleshooting

- Added durability and reliability

- Turnkey assemblies from a single source